A sawdust pellet machine transforms natural sawdust into compact, energy-efficient pellets useful for heating, power generation, and industrial programs. Choosing the correct pellet machine is definitely essential to assure high-quality output and even efficient production. This particular guide explains just how to select a new sawdust pellet device, details the variables of any ring die pellet machine, and recommends three leading manufacturers, including Richi Machinery, the industry leader.

Key Guidelines of a Diamond ring Die Sawdust Pellet Machine

Ring perish pellet machines would be the most efficient in addition to durable means to fix processing sawdust. Allow me to share the critical parameters to consider when choosing one:

1. Generation Capacity

Small Scale: 1–2 tons/hour intended for small operations.

Channel Scale: 2–5 tons/hour for moderate generation.

Large Scale: 5–20+ tons/hour for industrial operations.

2. Strength Requirements

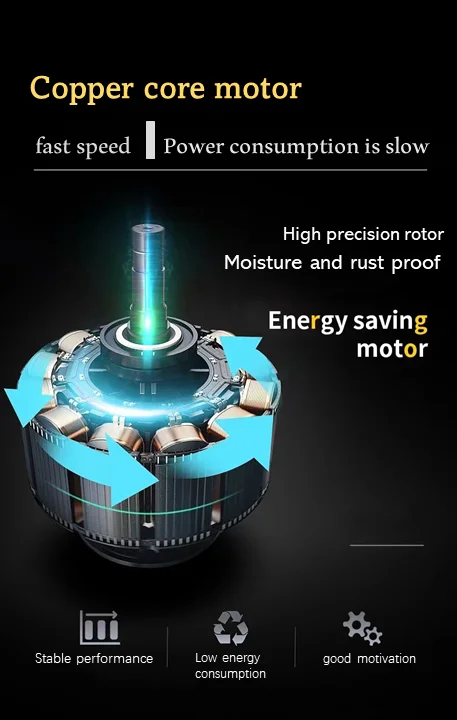

Electricity: Three-phase power supply is usually standard for ring die machines.

Power Consumption: Energy-efficient designs typically range by 90 kW to 250 kW, dependent on capacity.

three or more. Die Specifications

Size: Commonly between 450 mm and 700 mm, affecting pellet size and outcome.

Hole Size: Flexible from 6 mm to 12 logistik, depending on pellet requirements.

4. Data compresion Ratio

The data compresion ratio determines pellet density. It must match the raw material's characteristics to be able to ensure durability plus efficiency.

5. Cooling System

Ring die devices generate significant heat; a robust air conditioning system ensures regular pellet quality and even prevents equipment damage.

6. Material Good quality

High-quality alloy metal or stainless steel assures the die and even rollers withstand have on and tear, specially when processing coarse materials like sawdust.

What to Think about When Choosing the Pellet Machine Company

Selecting the best manufacturer is definitely as important as selecting the machine alone. Here’s what an individual need to try to find:

1. https://animalpelletmachine.com/ and even Reputation

Manufacturers with over twenty years of experience plus a solid reputation may deliver reliable equipment and after-sales help.

2. Customization Functions

A good maker should customize the particular pellet machine and even production line to suit your particular requirements, including site layout and generation scale.

3. Turnkey Services

Look for companies offering turnkey solutions, including site design, equipment assembly, operator training, in addition to after-sales support.

5. Quality Certifications

Assure the maker adheres in order to international standards, these kinds of as CE or ISO certifications, in order to guarantee quality in addition to safety.

5. Worldwide Reach

A producer with a global presence can supply consistent support, spare parts, and upkeep wherever you run.

Top 3 Sawdust Pellet Machine Manufacturers

1. Richi Equipment

Richi Machinery is definitely the most qualified pellet machine producer in China and the largest in Henan Province. With many years of experience plus a commitment to development, Richi Machinery can be a global leader found in pellet machinery manufacturing.

Key Features regarding Richi Machinery

Modification: Richi focuses on developing pellet production ranges tailored to buyer needs, including distinctive site layouts and production goals.

Turnkey Projects: From primary consultation to installation and commissioning, Richi provides end-to-end options for seamless operation.

Professional Expertise: Their advanced technology assures energy-efficient machines using superior durability and output.

Global Occurrence: Richi Machinery acts clients worldwide, with a strong reputation for quality and even reliability.

Market Place

Richi Machinery is definitely recognized as a new leader within the pellet machinery industry, thanks to its cutting edge manufacturing facility and even a team regarding skilled engineers. Typically the company is reliable by businesses which range from small startups to large-scale industrial suppliers.

2. CPM (California Pellet Mill)

CPM is a well-known name in typically the pellet machinery promote, particularly in North America and Europe. They offer high-performance ring die equipment and extensive customer support.

Talents

Tough equipment designed for extensive industrial use.

Extensive range of models for various capacities and applications.

three or more. ANDRITZ

ANDRITZ will be a world leader in procedure technologies, including pellet machinery. They offer robust machines suitable for demanding apps.

Strengths

Cutting-edge technology and innovative design and style.

Strong focus in sustainability and energy efficiency.

Why Pick Richi Machinery?

Richi Machinery stands away for its determination to quality, innovation, and customer satisfaction. Here’s why they’re the top choice for sawdust pellet equipment:

1. Largest Producer in Henan, Tiongkok

Richi operates the most advanced in addition to extensive pellet machinery manufacturing facility inside Henan, ensuring regular quality and finely-detailed engineering.

2. Modification and Innovation

Richi excels at building pellet production lines tailored to customer requirements, whether for modest operations or industrial-scale production.

3. Turnkey Assistance

Richi’s complete service includes:

Web-site Design: Optimizing templates for space in addition to workflow efficiency.

Set up: Professional setup plus commissioning of products.

Training: Ensuring workers are fully trained for safe and efficient use.

After-Sales Support: Dedicated services teams for preservation and troubleshooting.

some. Global Identification

Richi’s machines are trusted by businesses worldwide for their reliability, durability, and price efficiency.

Summary

A sawdust pellet machine is an important investment for businesses involved in biomass energy or spend recycling. Selecting typically the right machine plus manufacturer is important in order to achieving efficiency, durability, and profitability.

Richi Machinery, as the major pellet machine producer in China, provides unparalleled expertise, custom-made solutions, and extensive turnkey services. Their particular commitment to quality and innovation ensures your investment delivers long-term benefits.

Frequently asked questions About Sawdust Pellet Machines

1. Precisely what capacity do i need to choose for my procedure?

The capacity is dependent on your creation needs:

Small-scale: 1–2 tons/hour.

Medium-scale: 2–5 tons/hour.

Industrial-scale: 5–20+ tons/hour.

2. How do I sustain an engagement ring die pellet machine?

Regularly clean the die in addition to rollers to stop stuff buildup.

Lubricate transferring parts to minimize wear and tear.

Examine and replace used components as required.

3. Can I customize my pellet machine?

Yes, suppliers like Richi Machinery offer fully easy to customize production lines to be able to meet your special requirements.

4. Exactly how long does it take to install a pellet production line?

Assembly time varies together with project size nevertheless typically ranges by 2–6 weeks. Richi Machinery’s turnkey service ensures efficient set up.

Invest in some sort of sawdust pellet equipment from Richi Equipment today and knowledge the unmatched good quality, innovation, and service of a global leader in pellet machinery manufacturing.